| Availability: | |

|---|---|

Purchase Notes

Based on T6, T652 is conducted a certain amount of permanent deformation stretching to eliminate the internal stress, so that the cutting and processing is not easy to deform.

Product Parameter

7075 is an aluminum alloy with zinc as the main trace element. It has the highest strength among all the aluminium and excellent mechanical and anodic reaction. It could be applied for aircraft structure, die, jig, mechanical equipment, precision workpiece, etc.

Chemical composition ,Standard (max), W% | Al: balance | ||||||

Si | Fe | Cu | Mn | Mg | Zn | Cr | Other |

0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 5.1-6.1 | 0.18-0.28 | Zr+Ti0.25 |

Mechanical Property | T6 | T651 |

Tensile Strength(MPa) | ≥ 540 | ≥ 540 |

Yield Strength(MPa) | ≥ 470 | ≥ 470 |

Elongation(%) | ≥6 | ≥6 |

The above values is sbjuect to be different due to the different thickness.

Product Description

Aluminium alloy 7075 is a very high strength alloy that can match the strength of many steels while giving a considerable weight saving advantage. 7075 is produced by alloying Aluminium with Zinc, Magnesium and copper.

Due to its strength this alloy is typically used in molds for tools, bike frames and other sports equipments. Alloy 7075 is also commonly used in the automotive and aviation industries

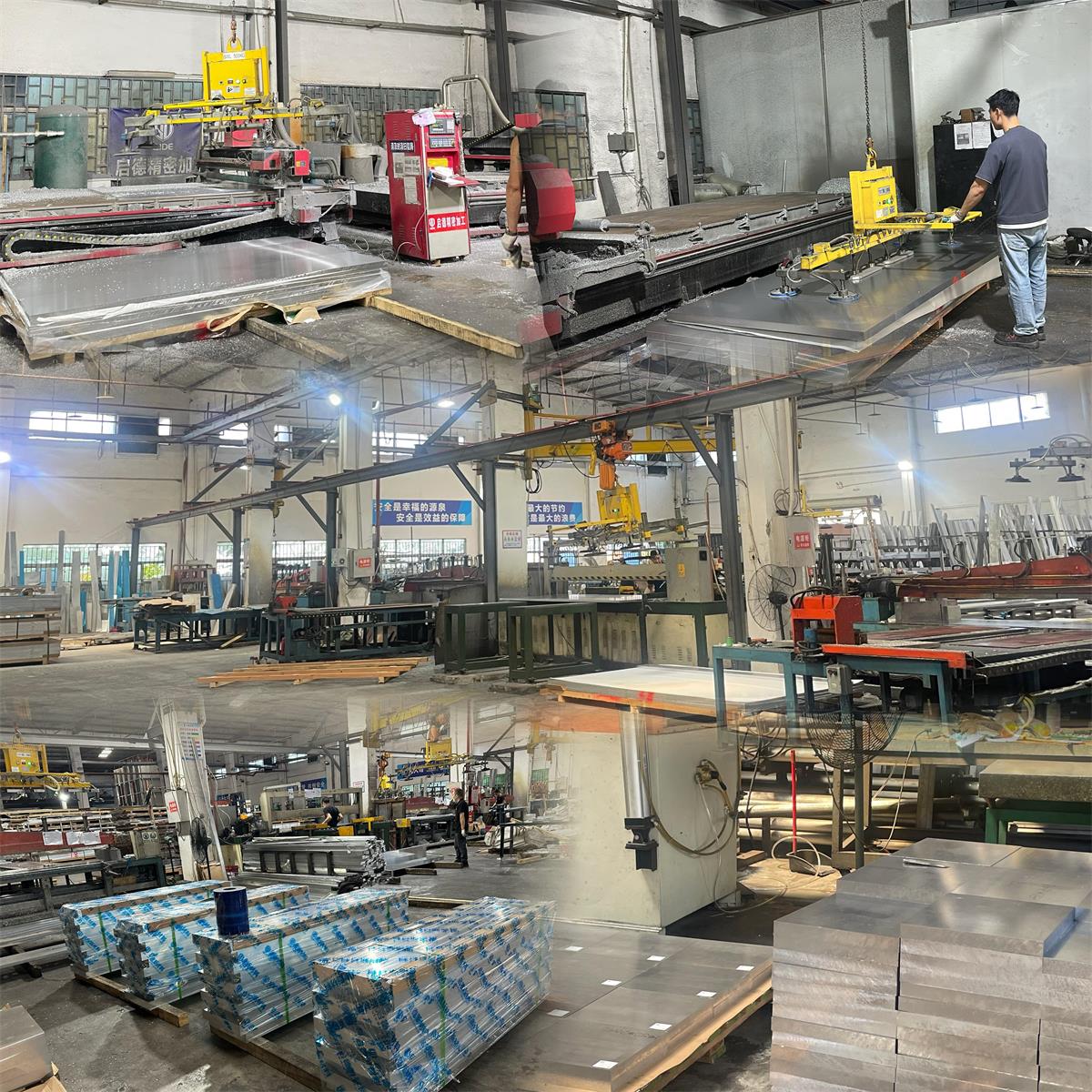

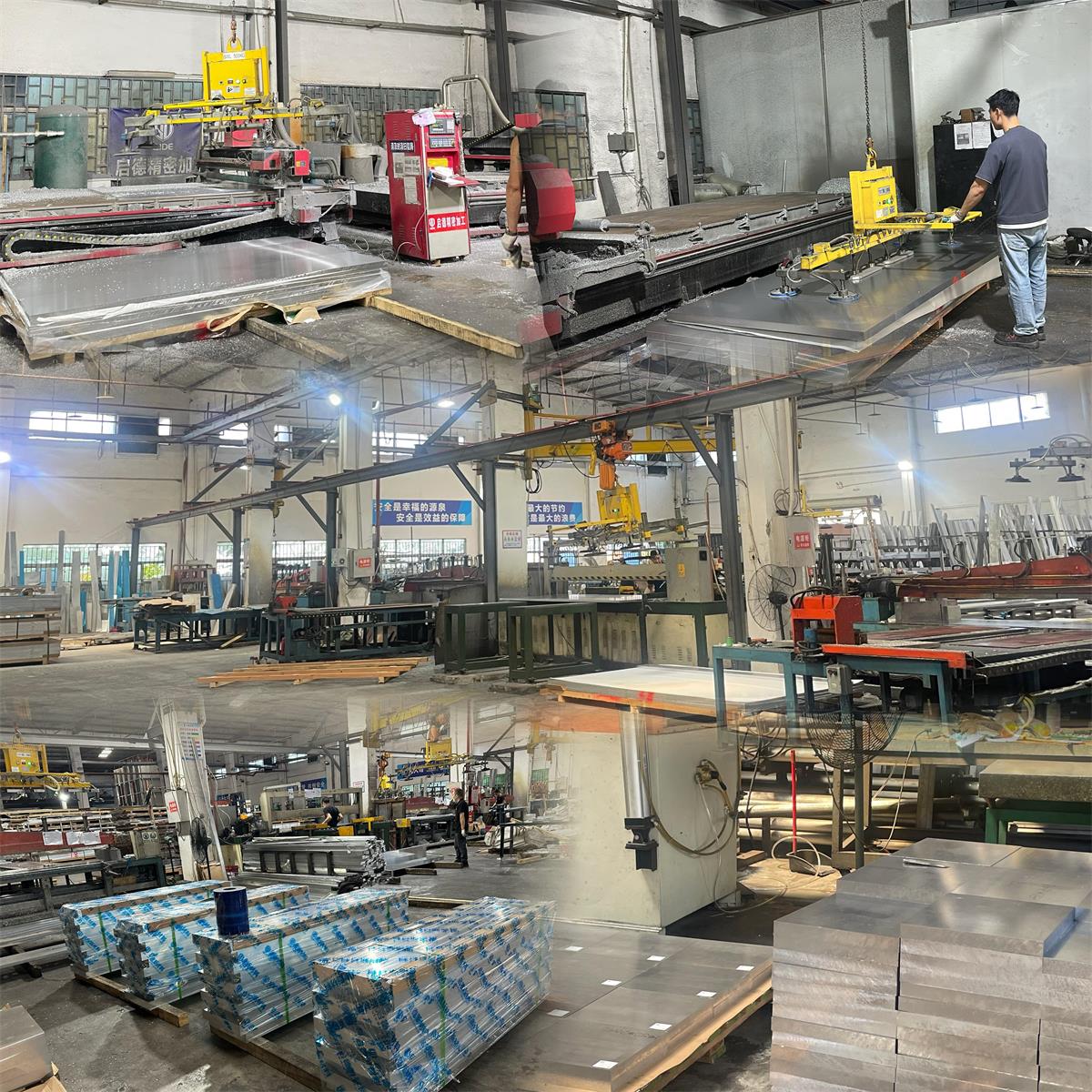

The interior has been scanned and tested by various advanced instruments.

Smooth surface, high flatness.

Thickness tolerance about ±1%.

Thickness<100mm, there is a protective film covering the surface (random color).

We have more than ten cutting equipment and machines.

Thickness<8mm, we sale whole plate only. The whole plate is able to be cut to smaller size.

Thickness not less than 8mm, we sale the small pieces in any dimensions.

Our system ensures all the products are traceable to provide the original factory certificate.

Purchase Notes

Based on T6, T652 is conducted a certain amount of permanent deformation stretching to eliminate the internal stress, so that the cutting and processing is not easy to deform.

Product Parameter

7075 is an aluminum alloy with zinc as the main trace element. It has the highest strength among all the aluminium and excellent mechanical and anodic reaction. It could be applied for aircraft structure, die, jig, mechanical equipment, precision workpiece, etc.

Chemical composition ,Standard (max), W% | Al: balance | ||||||

Si | Fe | Cu | Mn | Mg | Zn | Cr | Other |

0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 5.1-6.1 | 0.18-0.28 | Zr+Ti0.25 |

Mechanical Property | T6 | T651 |

Tensile Strength(MPa) | ≥ 540 | ≥ 540 |

Yield Strength(MPa) | ≥ 470 | ≥ 470 |

Elongation(%) | ≥6 | ≥6 |

The above values is sbjuect to be different due to the different thickness.

Product Description

Aluminium alloy 7075 is a very high strength alloy that can match the strength of many steels while giving a considerable weight saving advantage. 7075 is produced by alloying Aluminium with Zinc, Magnesium and copper.

Due to its strength this alloy is typically used in molds for tools, bike frames and other sports equipments. Alloy 7075 is also commonly used in the automotive and aviation industries

The interior has been scanned and tested by various advanced instruments.

Smooth surface, high flatness.

Thickness tolerance about ±1%.

Thickness<100mm, there is a protective film covering the surface (random color).

We have more than ten cutting equipment and machines.

Thickness<8mm, we sale whole plate only. The whole plate is able to be cut to smaller size.

Thickness not less than 8mm, we sale the small pieces in any dimensions.

Our system ensures all the products are traceable to provide the original factory certificate.