| Availability: | |

|---|---|

Product parameter

Trace elements of magnesium - based aluminum alloy, representative moderate strength, good welding, processing, especially high fatigue strength, good corrosion resistance to sea water.

It could be used for office equipment, camera, vehicle and ship sheet metal parts, instrument, shell, surface bright parts, etc.

Chemical composition ,Standard (max), W% | Al: balance | ||||||

Si | Fe | Cu | Mn | Mg | Zn | Cr | Other |

0.25 | 0.4 | 0.1 | 0.31 | 2.2-2.8 | 0.1 | 0.15-0.35 | - |

Mechanical Property (Standard Value) | O | H32 | H112 |

Tensile Strength(MPa) | ≥170 | ≥210 | ≥210 |

Yield Strength(MPa) | ≥65 | ≥130 | ≥130 |

Elongation(%) | ≥18 | ≥7 | ≥10 |

Product Description

Aluminium Alloy 5052 is a medium strength, Aluminium magnesium with good resistance to atmospheric corrosion. It can attain moderate to high strength by cold working and has relatively high welded strength compared to other Aluminium Alloys. It is the alloy of choice for sheet work done for outdoor uses due to its bendibility and corrosion resistance.

Aluminium alloy is widely used for manufacture of appliances, small boats, signage,Packaging, Architectural components and facades, cabinets and enclosures.

The interior has been scanned and tested by various advanced instruments.

Smooth surface, high flatness.

Thickness tolerance about ±1%.

Thickness<100mm, there is a protective film covering the surface (random color).

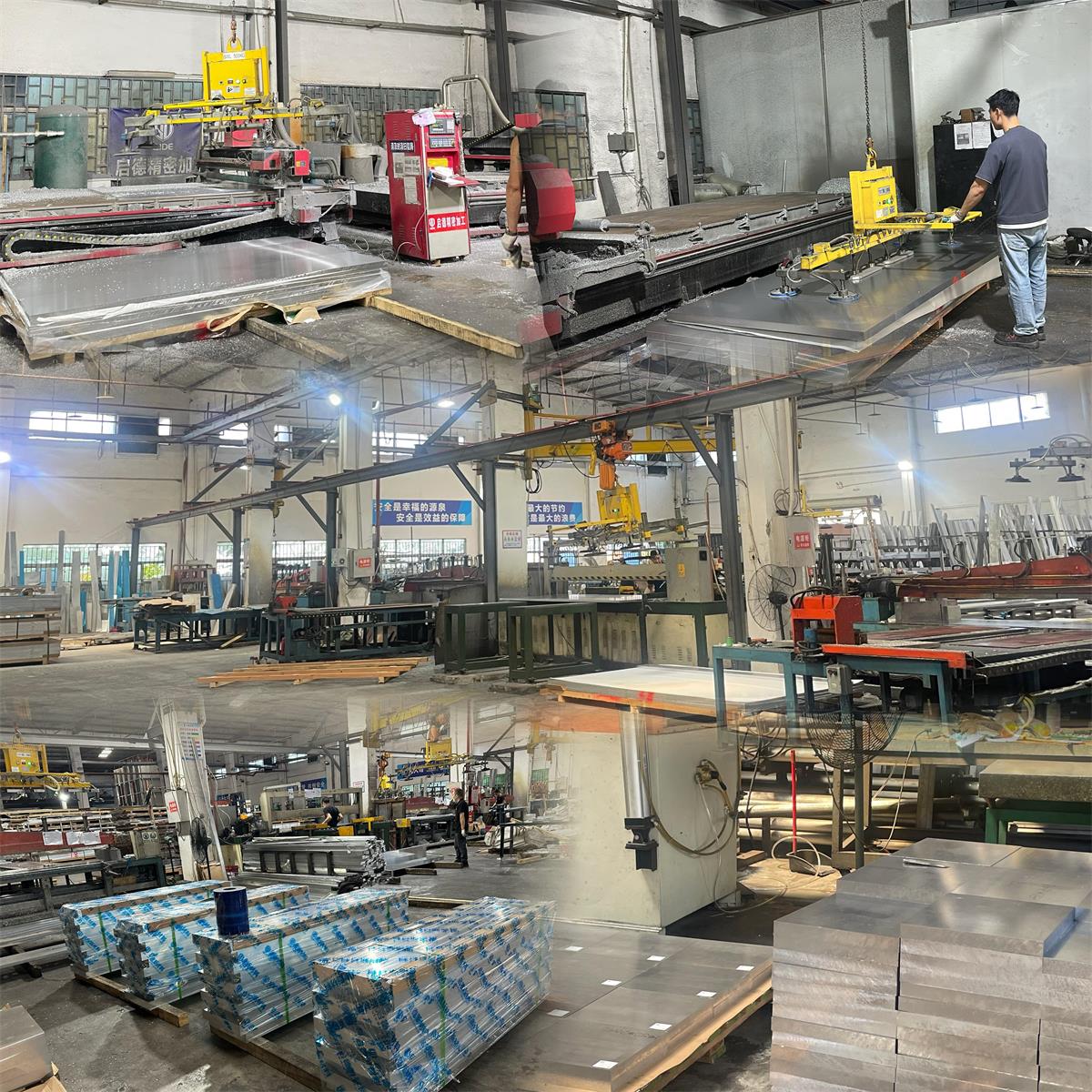

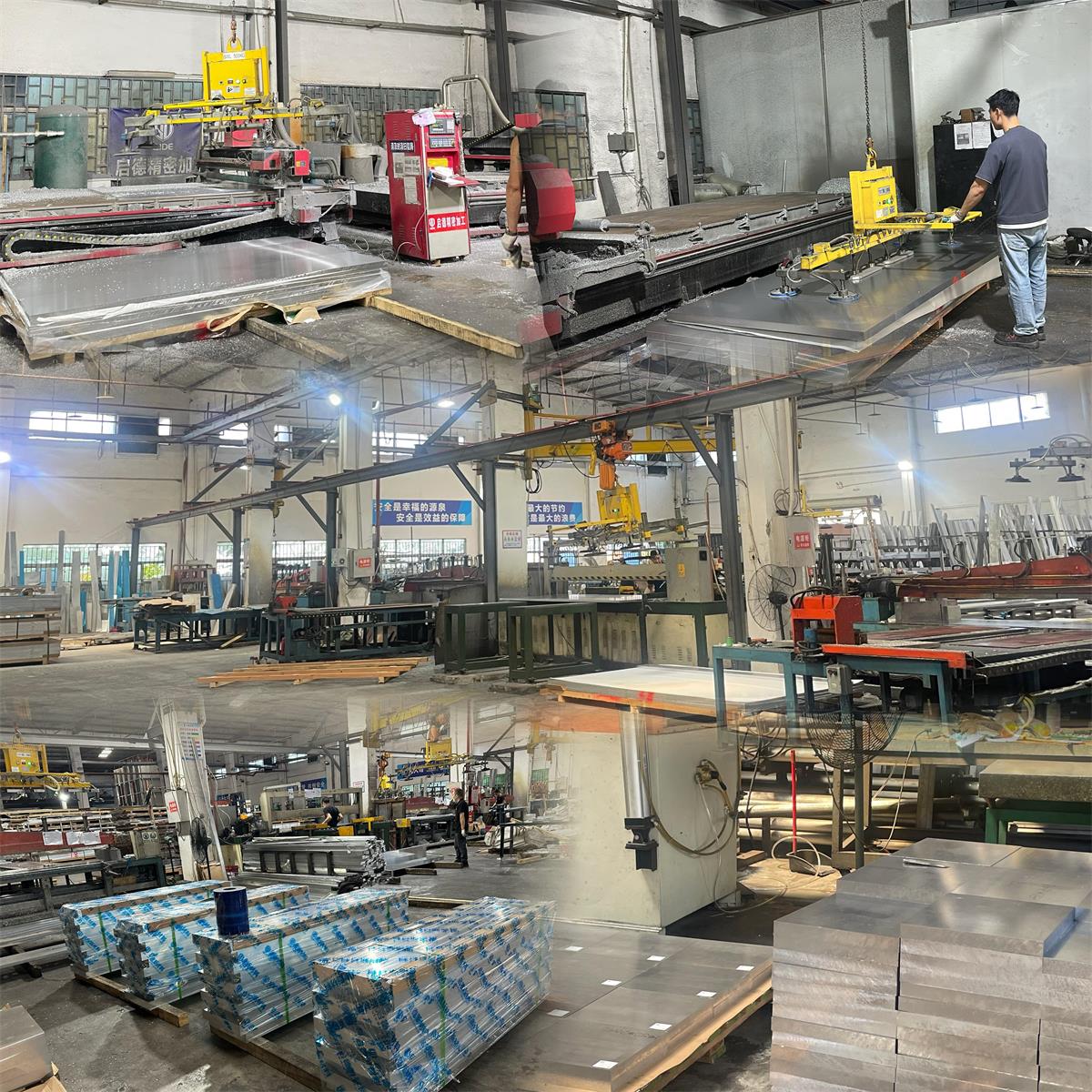

We have more than ten cutting equipment and machines.

Thickness<8mm, we sale whole plate only. The whole plate is able to be cut to smaller size.

Thickness not less than 8mm, we sale the small pieces in any dimensions.

Our system ensures all the products are traceable to provide the original factory certificate.

Product parameter

Trace elements of magnesium - based aluminum alloy, representative moderate strength, good welding, processing, especially high fatigue strength, good corrosion resistance to sea water.

It could be used for office equipment, camera, vehicle and ship sheet metal parts, instrument, shell, surface bright parts, etc.

Chemical composition ,Standard (max), W% | Al: balance | ||||||

Si | Fe | Cu | Mn | Mg | Zn | Cr | Other |

0.25 | 0.4 | 0.1 | 0.31 | 2.2-2.8 | 0.1 | 0.15-0.35 | - |

Mechanical Property (Standard Value) | O | H32 | H112 |

Tensile Strength(MPa) | ≥170 | ≥210 | ≥210 |

Yield Strength(MPa) | ≥65 | ≥130 | ≥130 |

Elongation(%) | ≥18 | ≥7 | ≥10 |

Product Description

Aluminium Alloy 5052 is a medium strength, Aluminium magnesium with good resistance to atmospheric corrosion. It can attain moderate to high strength by cold working and has relatively high welded strength compared to other Aluminium Alloys. It is the alloy of choice for sheet work done for outdoor uses due to its bendibility and corrosion resistance.

Aluminium alloy is widely used for manufacture of appliances, small boats, signage,Packaging, Architectural components and facades, cabinets and enclosures.

The interior has been scanned and tested by various advanced instruments.

Smooth surface, high flatness.

Thickness tolerance about ±1%.

Thickness<100mm, there is a protective film covering the surface (random color).

We have more than ten cutting equipment and machines.

Thickness<8mm, we sale whole plate only. The whole plate is able to be cut to smaller size.

Thickness not less than 8mm, we sale the small pieces in any dimensions.

Our system ensures all the products are traceable to provide the original factory certificate.